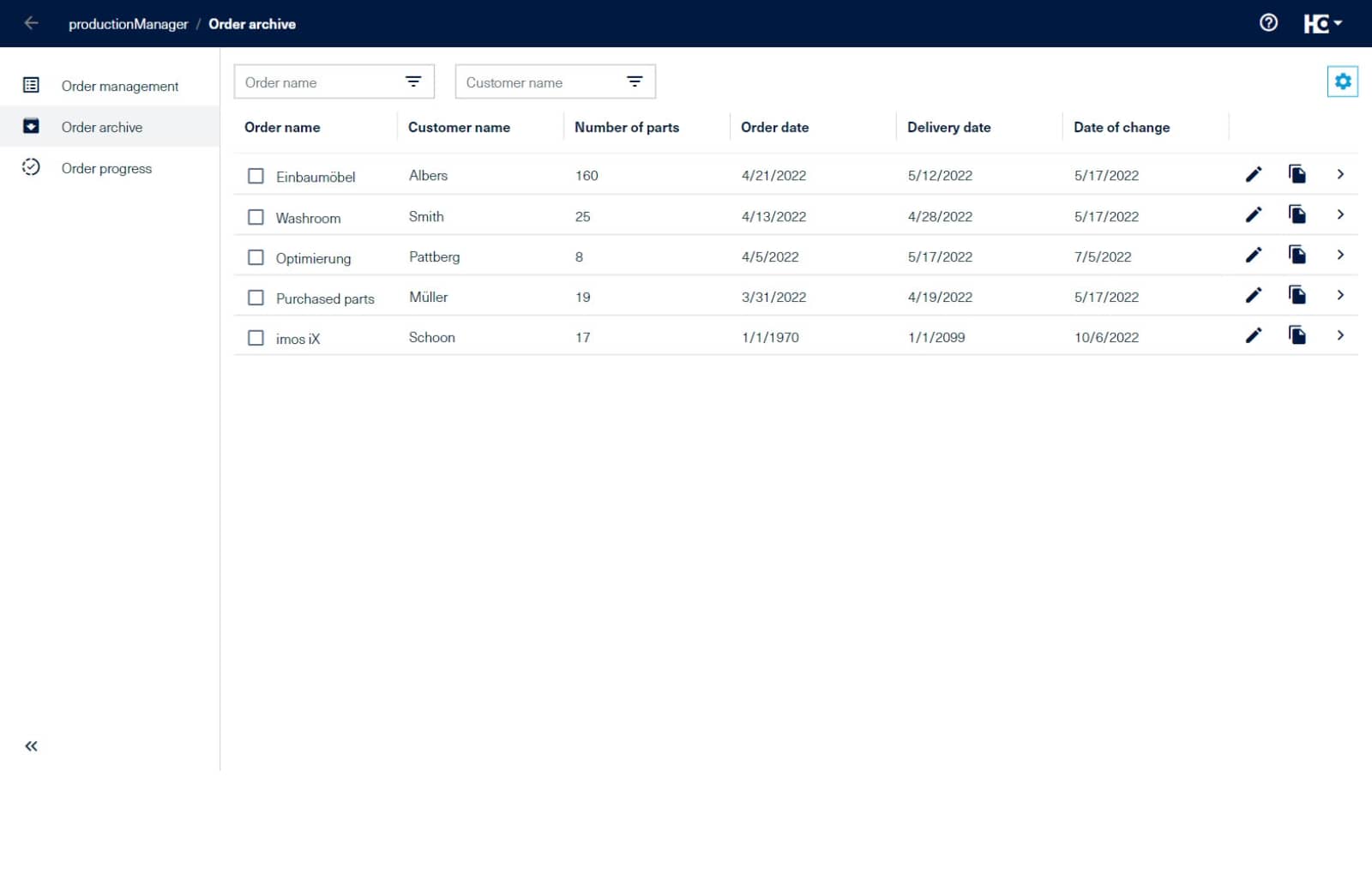

Orderoverzicht

bewaren

#vakwerkgaatdigitaal

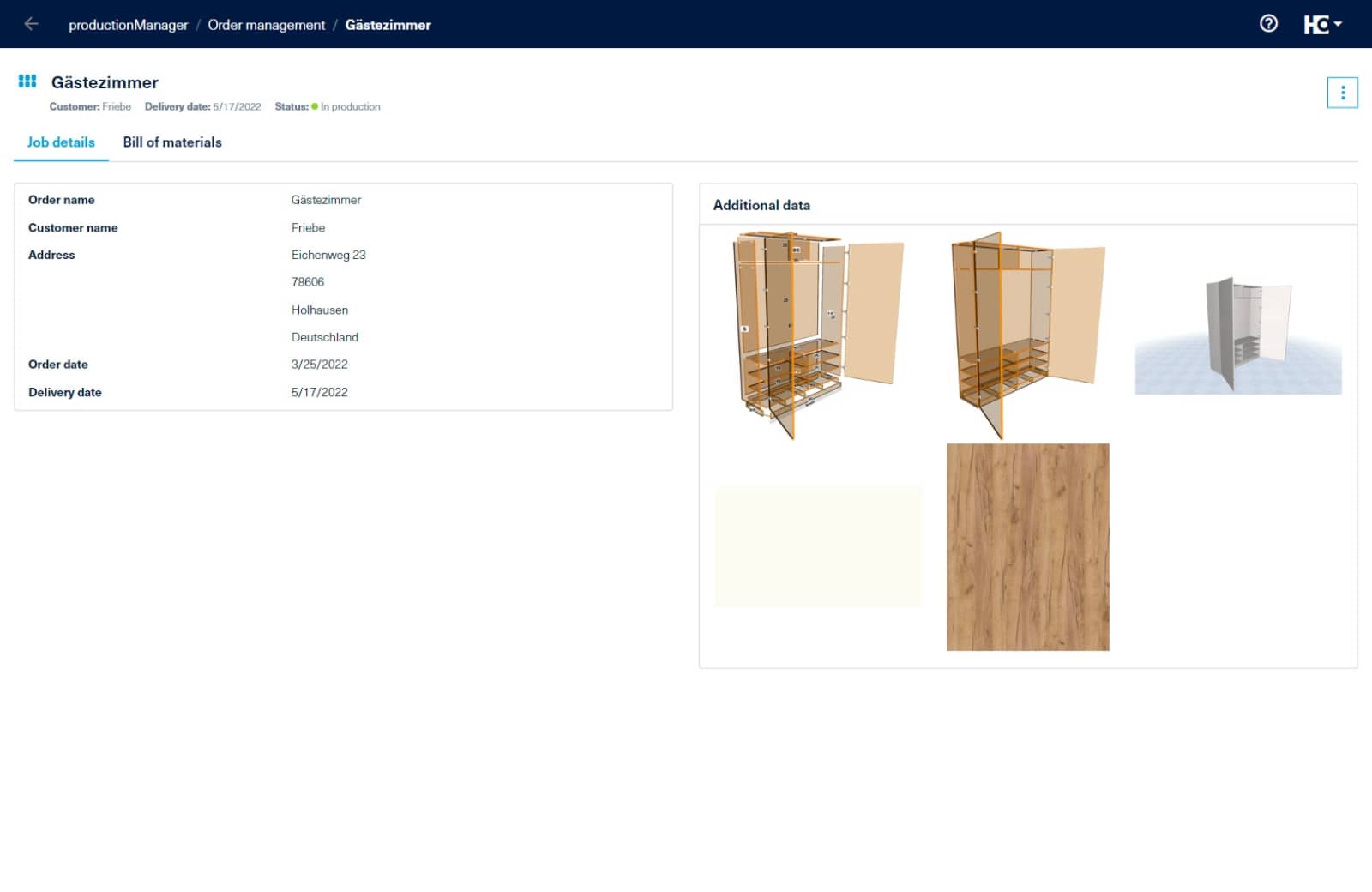

De digitale ordermap

productieManager

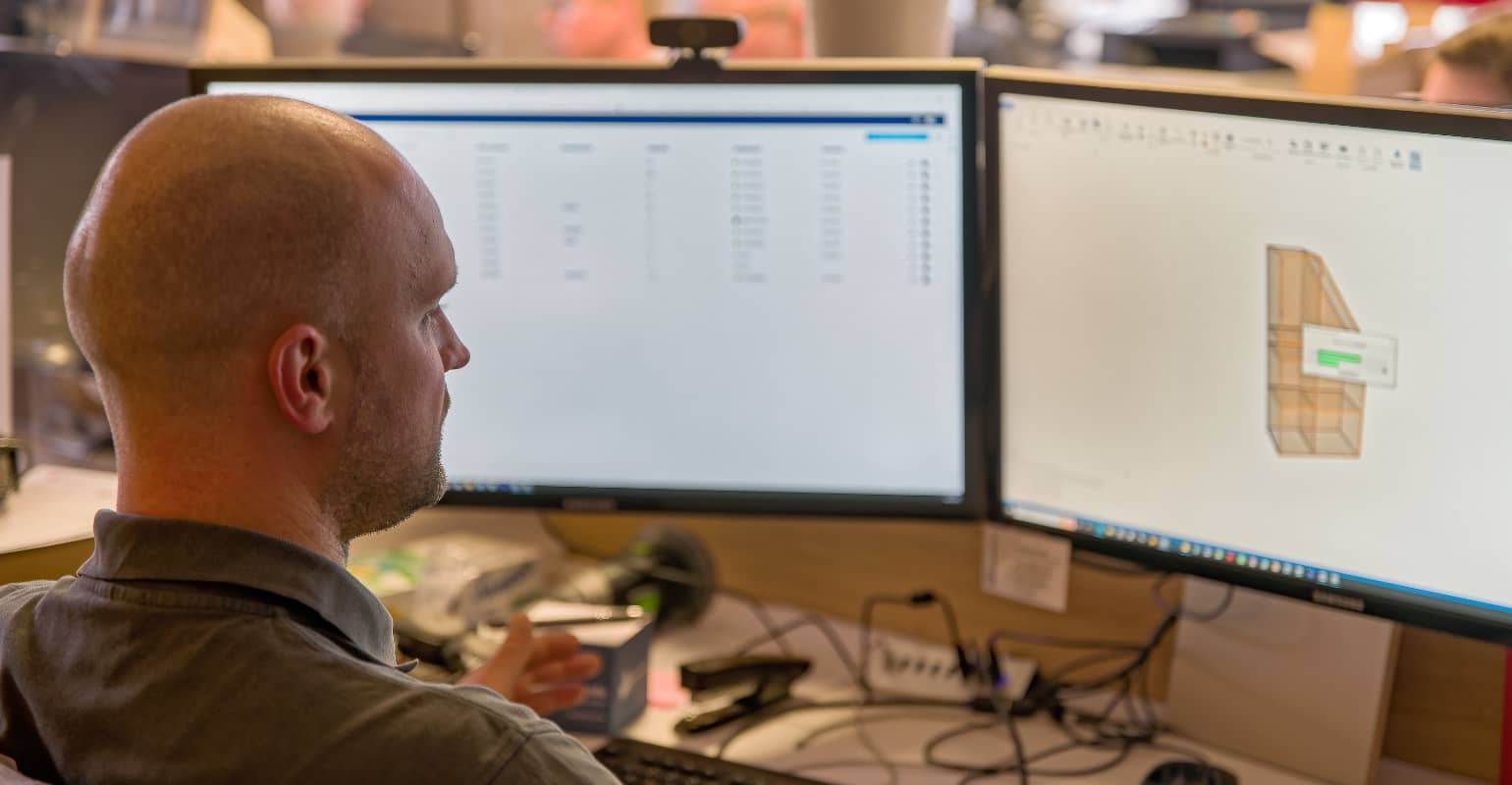

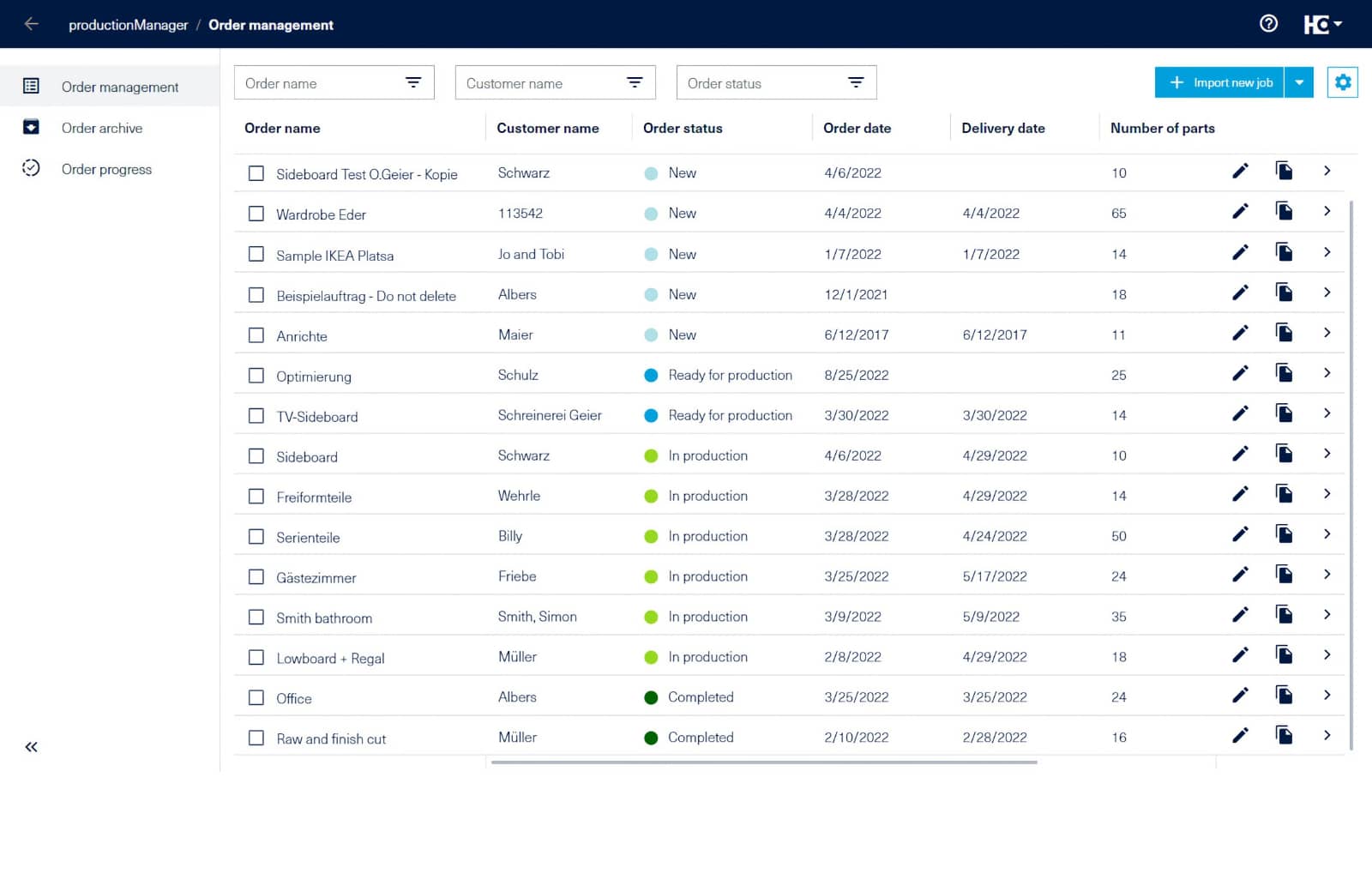

Geen papierwerk meer: De digitale ordermap brengt transparantie in de werkplaats. De orderboeken voor veel schrijnwerkers en timmerlieden zijn vol. Dit vergroot de uitdaging om het overzicht te behouden en de ordergegevens voor alle medewerkers up-to-date te houden. Zeker als de medewerkers in de werkvoorbereiding, in de productie of in de bankkamer zitten. De oplossing voor de informatiechaos: de digitale ordermap. Voortaan heeft iedereen in realtime toegang tot alle informatie over elk order.

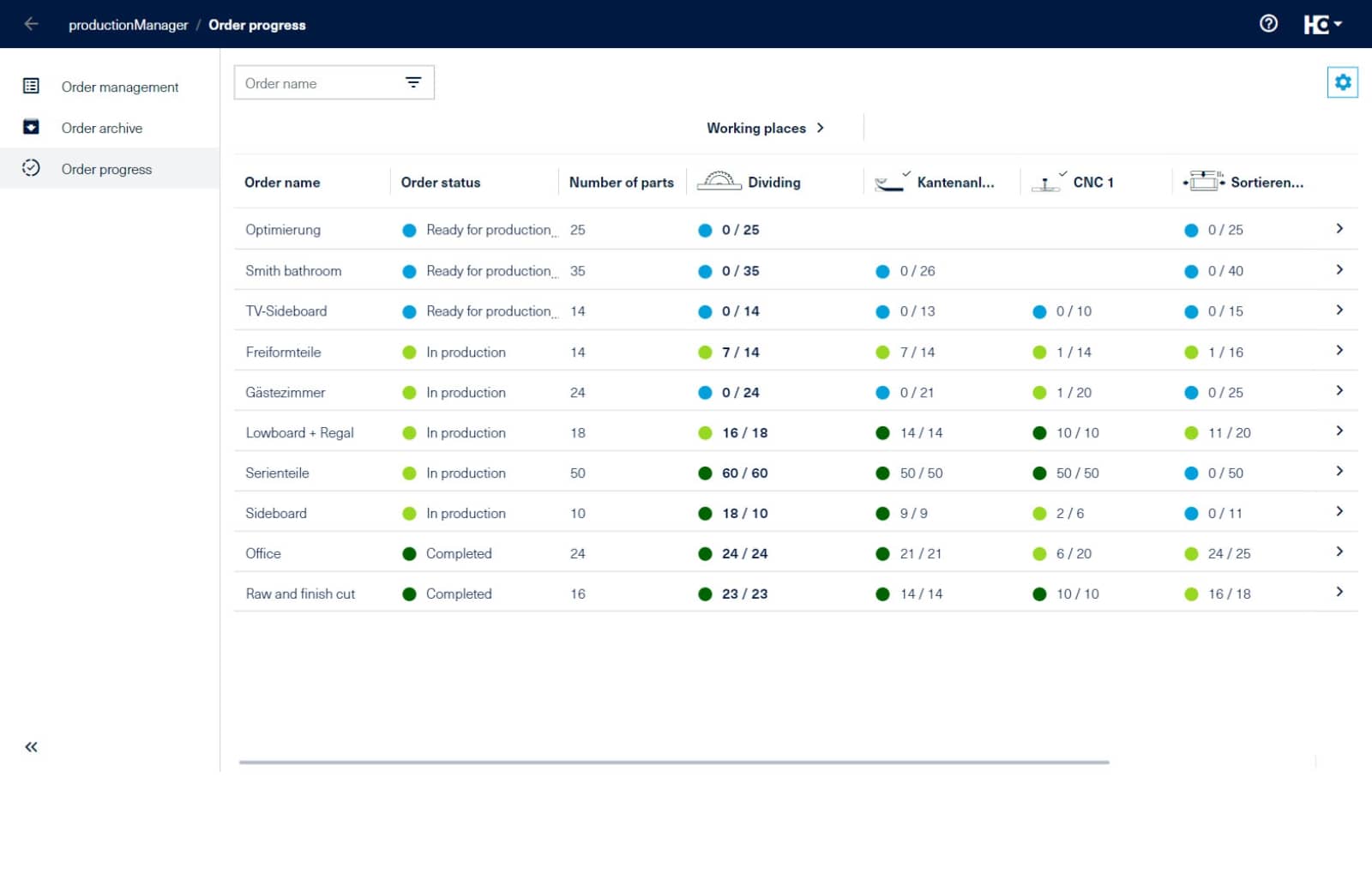

Maar dat niet alleen: de web-app maakt ook de actuele voortgang van het werk van de afzonderlijke componenten transparant voor alle betrokkenen. Zo heeft u altijd inzicht in de status van uw orders. De app kan door iedereen met een laptop of tablet worden gebruikt.

Gratis gebruiken

Uw voordeel

- Iedereen heeft alles in zicht: Of het nu gaat om kantoor, productie of montage – iedereen heeft op elk moment toegang tot alle gegevens.

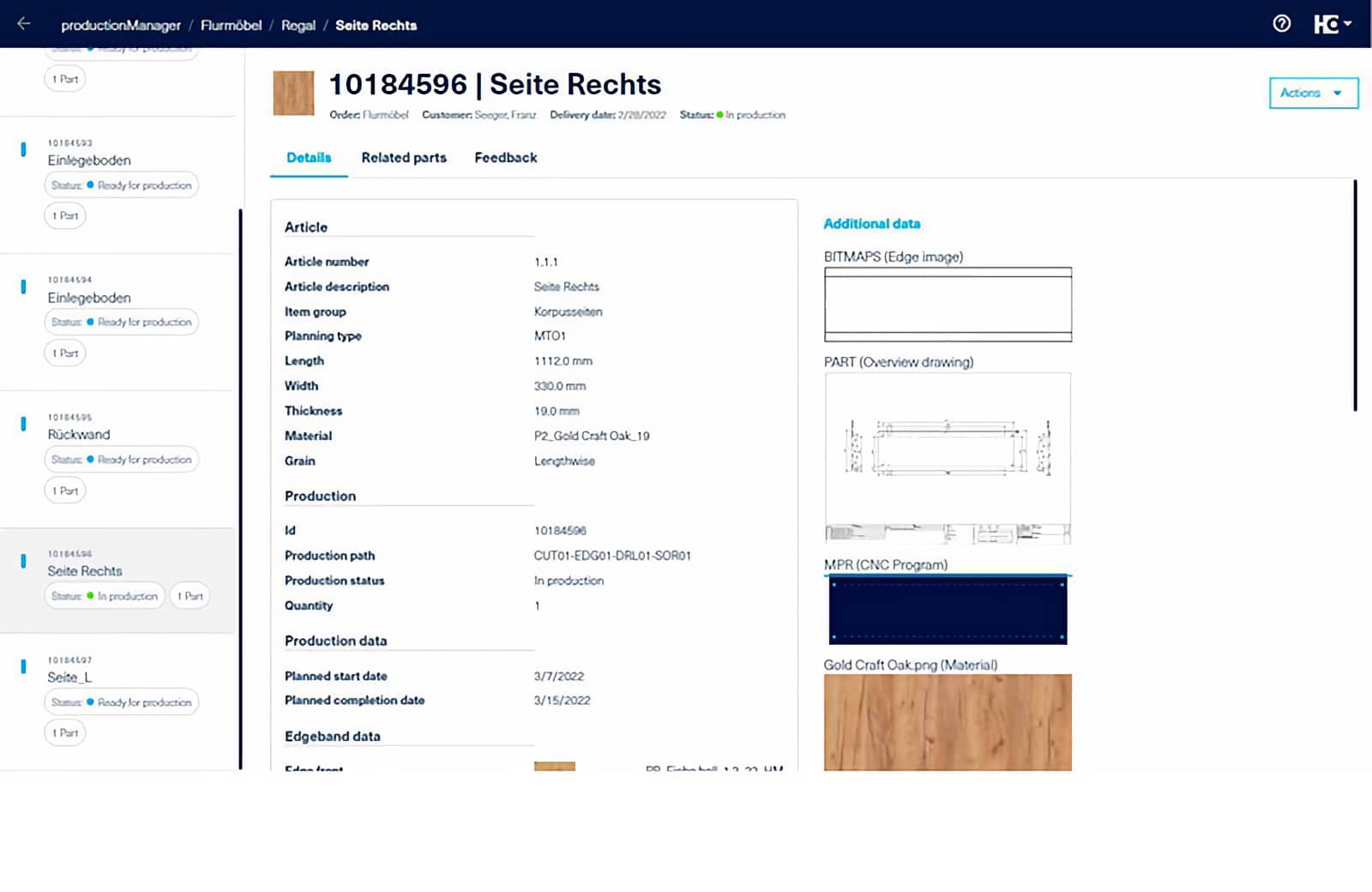

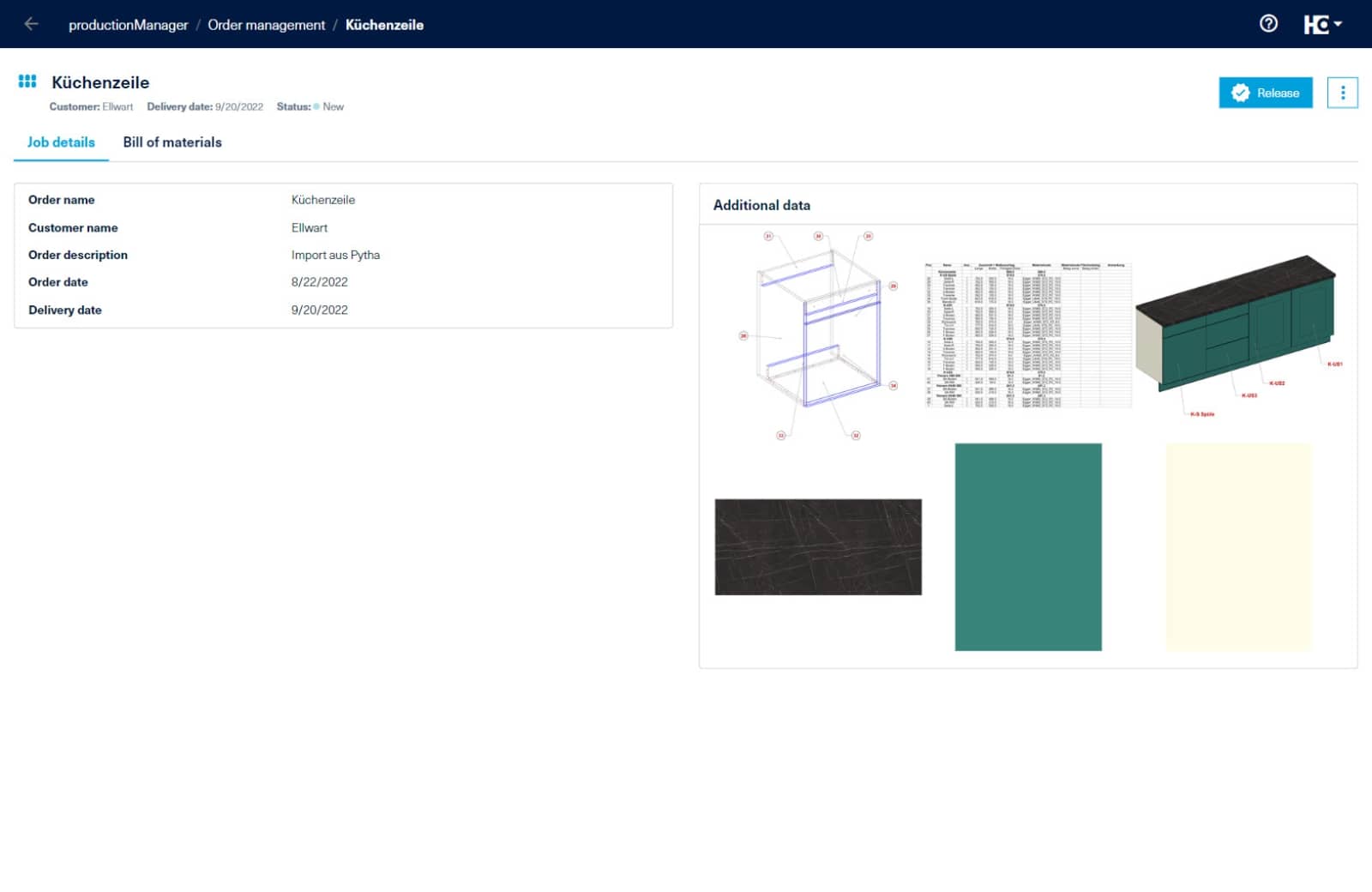

- Eenvoudige data-import: Maak een nieuw order aan of importeer deze vanuit een CAD/CAM-systeem, een brancheoplossing of Excel. Dan zijn alle details digitaal voor u beschikbaar (artikelen, bouwgroepen, onderdelen met tekeningen).

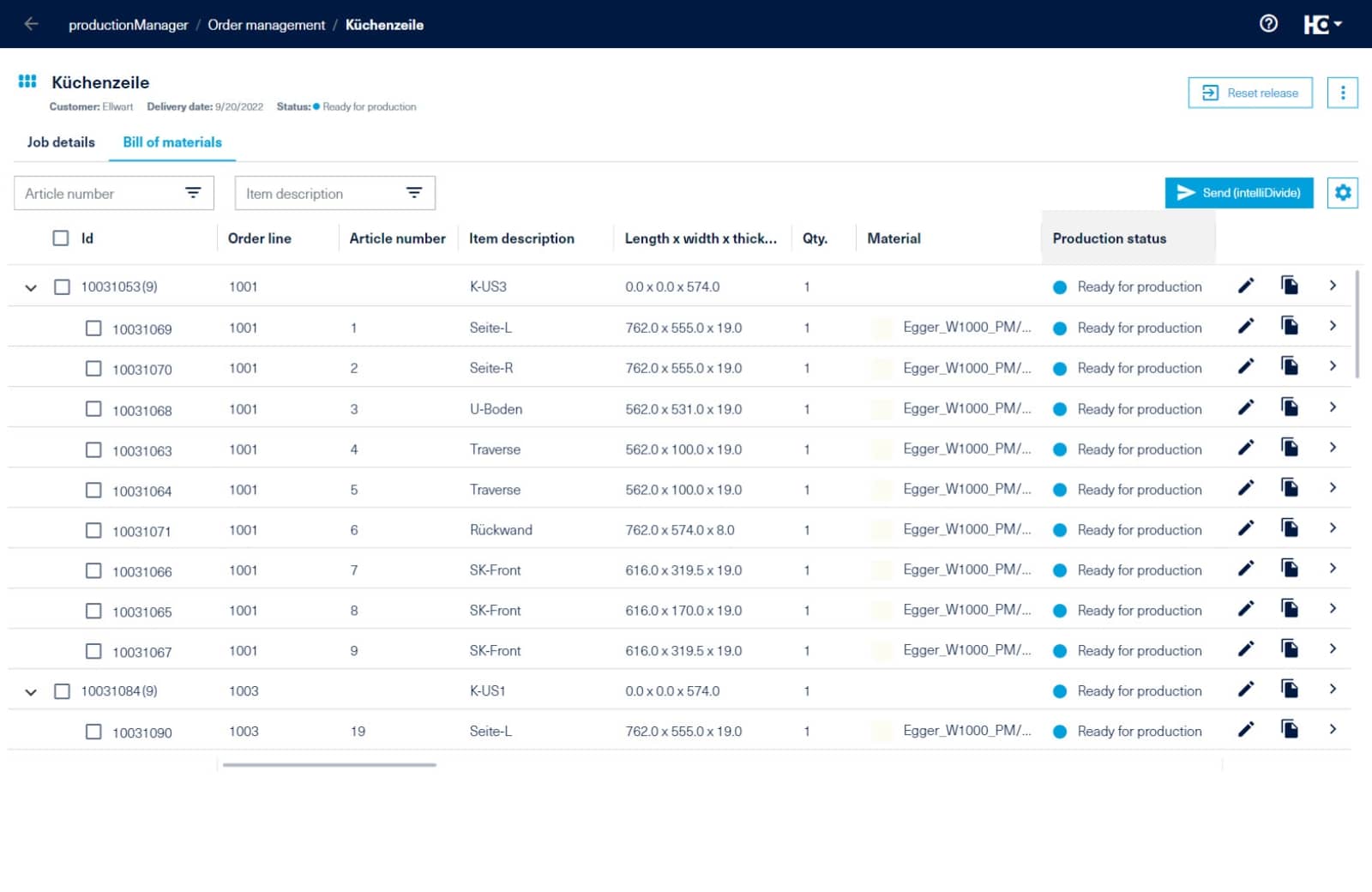

- Batchvorming met één klik: Indien nodig kunt u de “batchvorming” bijboeken. Met deze optie kunt u opdrachten voor productiepartijen samenvoegen en als maatzaaglijst exporteren of naar intelliDivide (optimalisatie voor op maat zagen) verzenden. Bundelt uw opdrachten volgens verschillende kengetallen (bijv. dezelfde materialen) en verlaag zo het materiaalverbruik. Andere interessante kengetallen geven u inzicht in de gevolgen van uw gevormde batches voor de productie.

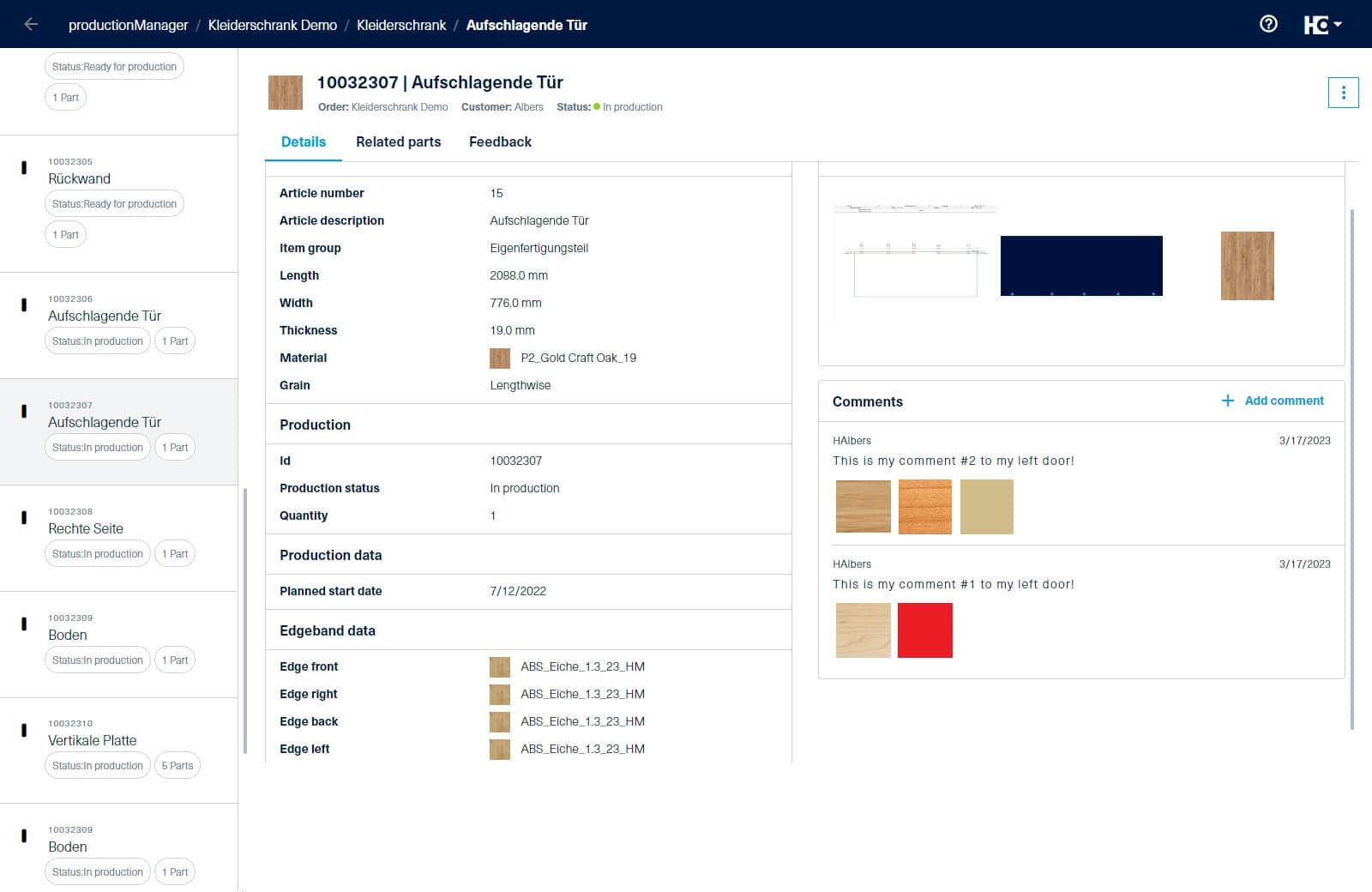

- Eenvoudige naproductie van onderdelen: indien nodig is de optie ”Naproductie“ beschikbaar. Leg nagemaakte onderdelen vast en lever informatie over de fout van het onderdeel, foto's of commentaren. Ook is informatie voor de verantwoordelijke medewerker mogelijk. Het onderdeel wordt direct in de productionManager weergegeven en wordt optimaal in het productieproces opgenomen.

- Realtime up-to-date: Alle medewerkers kunnen de ordervoortgang live volgen.

- Geen kosten: de productionManager is in de basisversie gratis. U kunt extra opties bijboeken naar behoefte. Een willekeurig aantal medewerkers kan de toepassing zonder extra kosten gebruiken.

- Geen updates of onderhoud nodig: De webgebaseerde software is altijd up-to-date en er zijn geen kosten nodig voor updates.

- Controle van uw datakwaliteit: Meer dan een digitale ordermap, want de productionManager zorgt voor de datakwaliteit van uw orders.

- Eenvoudige communicatiekanalen: Opmerkingen worden direct in de productionManager bij het betreffende onderdeel of artikel verzameld. Zo kunnen de commentaren worden weergegeven met betrekking tot onderdelen.

- Machinefeedback: De HOMAG-machine rapporteert automatisch aan de productiemanager welke componenten zijn verwerkt.

Wil je meer leren?

homag.com/productionmanagerWat onze klant zeggen

”Onze belangrijkste interesse was het traceren in de productie, zodat we altijd weten waar onze componenten zich op dat moment bevinden. Met zijn scala aan functies voldoet productionManager precies aan wat we zochten!“

Phillip Schuon, directeur MS-Schuon GmbH

”Voor het echte digitale gebruik beschikten we nog niet over een centrale tool. Iedereen in het team construeerde weliswaar al met SmartWOP zijn of haar opdrachten zelf en genereerde daarvoor ook alle productiegegevens. Maar hoe het daarna ging, kon gewoonweg niet meer worden gevolgd. De productionManager biedt nu uitkomst.“

Benjamin Löw, bedrijfsleider en meestermeubelmaker, Löw Breidenbach Möbelbau GmbH

“De productieManager wordt nu door ons gebruikt in de werkvoorbereiding, dit betekent dat dit de bouwsteen is waar we complete orders uit onze planningssoftware kunnen importeren en verwerken in de productieManager. Dat is een enorm voordeel. Alle medewerkers hebben dezelfde, huidige status en zien wijzigingen. We kunnen direct zien waar het order of het onderdeel zich bevindt.”

Oliver Geier (directeur Schrijnwerken Geier), Schrijnwerken Geier

“De filterinstellingen zijn erg handig. In principe geven we de volledige metadata aan de productie en kunnen we vervolgens met de voorgedefinieerde filters een individueel filter samenstellen voor elke werkplek of zelfs voor elke medewerker, zodat hij op dit punt alleen de informatie ziet die voor hem relevant is. Dat is geweldig.”

Jan Christoph Kahre-Heidemann (directeur Formatio Einrichtungen), Formatio Einrichtungen GmbH & Co. KG

”Dat was voor ons ook de reden om de productionManager sinds het begin van het jaar te testen en gebruiken, omdat hij als geen ander systeem deze transparantie biedt. Het belangrijkste punt was om het volledige orderoverzicht in de gaten te houden, dus ook het termijnbeheer altijd onmiddellijk te registreren.“

Katharina Höppner (medewerker en projectmanager), ZB Holzsysteme

”De digitale ordermap biedt mijn team en mij een continu werkproces. Elke medewerker heeft toegang tot alle informatie, ongeacht waar hij zich op dat moment in het bedrijf bevindt. Dat zorgt voor een optimaal orderoverzicht en een efficiënte werkwijze.”

Manuel zum Buttel (directeur ZB Holzsysteme), ZB Holzsysteme

Dit is misschien ook interessant voor u:

Meer oplossingen.

Ervaringen uit de praktijk:

De producten in gebruik.